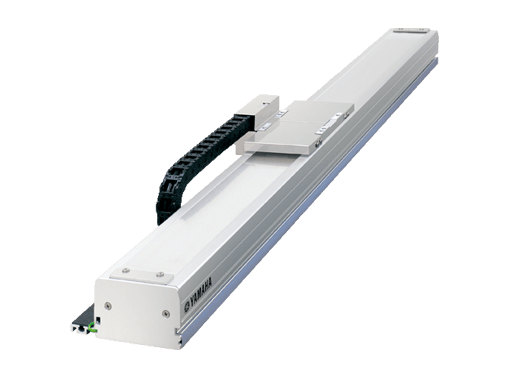

YAMAHA SCARA Roboter YKX Serie

Durch den vollständigen Verzicht auf Riemen und die weitere Verstärkung der Antriebssysteme wird die branchenweit kürzeste Zykluszeit erreicht.

Vertriebsingenieur Manfred Göschl berät Sie gerne:

+43 2623 20600 37

manfred.goeschl@fjmayer.at

Beschreibung

SCARA Roboter der YKX-Serie

Hohe Geschwindigkeit, hohe Genauigkeit und hohe Belastbarkeitauf dem höchsten Niveau der Branche.

- Armlänge: 250mm to 1000mm

- Max. Nutzlast: 21kg (YKX600, YKX800, YKX1000)

- Standard Zykluszeit: 0.28sec (YKX250, YKX400)

- Hohe Geschwindigkeit und hohe Belastbarkeit

Die einzigartige Struktur von YAMAHA mit direkt gekoppeltem Motor und Untersetzungsgetriebe (ohne Riemen) und verstärktem Antriebssystem sorgt für eine noch höhere Steifigkeit und hohe Bewegungsgeschwindigkeit.

Dies verbessert die praktischen Bewegungsleistungen mit einem Werkzeug und einem Werkstück, das tatsächlich in Position gehalten wird. Das Modell mit 400 mm Armlänge erreicht die Standard-Zykluszeit von 0,28 Sekunden und ist damit die kürzeste in der Branche.*

Laut YAMAHAs Umfrage: Standardzykluszeit des Modells mit 400 mm Armlänge – 0,28 Sekunden

2. Anschlusskabel vollständig vom Roboterkörper getrennt

Die Verbindungskabel des Roboters lassen sich leicht vom Robotergehäuse abnehmen. Dies erleichtert die Installation von Robotern und den Wechsel der Kabellänge.

Der Roboterarm ist so konstruiert, dass er über genügend Platz und Befestigungsschrauben verfügt, um Peripheriegeräte wie z. B. Benutzerwerkzeuge anzuschließen. Außerdem verfügt der Roboter standardmäßig über eine interne elektrische Verdrahtung und pneumatische Leitungen, die eine Vielzahl möglicher Anwendungen wie pneumatische Geräte, Magnetventile und Kamerageräte aufnehmen können. Dies erleichtert Ihnen die Einführung eines Robotiksystems.

3. Keine Rückkehr zum Ursprung erforderlich / Kompatibel mit Absolutpositionssystem ohne Batteriewechsel

Der Motor wird nach den Spezifikationen eines kompletten Absolutpositionssystems gefertigt.

Sie müssen die Einheiten nach der Trans-Installation oder Inbetriebnahme nicht an ihren Ursprungsort zurückbringen, was zu einer erheblichen Verringerung des Arbeitsaufwands beiträgt.

Ausgestattet mit dem absoluten Positionssystem, das keinen Batteriewechsel erfordert, müssen Sie die Batterie nicht austauschen.

Technische Daten

Specification

| YKX250 | YKX400 | YKX600 | YKX800 | YKX1000 | |||

|---|---|---|---|---|---|---|---|

| Axis Specifications | X Axis | Arm Length (mm) | 75 | 225 | 350 | 450 | 650 |

| Rotation Angle (°) | ±130 | ±140 | ±130 | ||||

| Y Axis | Arm Length (mm) | 175 | 250 | 350 | |||

| Rotation Angle (°) | ±150 | ±165 | |||||

| Z Axis | Stroke (mm) | 200 | 200 / 450 | ||||

| R Axis | Rotation Angle (°) | ±360 | |||||

| Motor Output (W) | X Axis/Y Axis/Z Axis/R Axis | 750 / 400 / 400 / 320 | |||||

| Maximum Speed | X-Y Axis Synthesis (m/s) | 4.9 | 6.2 | 8.8 | 11.2 | 12.9 | |

| Z Axis (m/s) | 2.8 | ||||||

| R Axis (°/s) | 1020 | ||||||

| Repeatability *1 | X-Y Axis (mm) | ±0.01 | ±0.02 | ||||

| Z Axis (mm) | ±0.01 | ||||||

| R Axis (°) | ±0.004 | ||||||

| Maximum Payload (kg) | 8 | 21 | |||||

| Standard Cycle Time (s)*2 | 0.28 | 0.28 | 0.33 | 0.34 | 0.38 | ||

| R Axis Allowable Inertia (kgm2)*3 | 1.05 | ||||||

| Wiring | IO1*4 | 0.15sq x 12 (no shield, straight) | |||||

| IO2*5 | 0.2sq x 6 (no shield, straight) | ||||||

| IO3*5 | 0.15sq x 8 (shielded, twisted pair) | ||||||

| Ethernet Cable*4 | 00.15sq x 8 (shielded, twisted pair) | ||||||

| Lighting Cable*4 | 0.5sq x 4 (no shield, straight) | ||||||

| Piping (outer diameter) | φ4 mm x 2 *4 φ6 mm x 2 *4 |

||||||

| Motion Limit Settings | 1.Soft limit 2. Mechanical stopper (X, Y, Z axes) | ||||||

| Supplied Cable (m) | 3、6、15 | ||||||

| Unit Weight (kg)*6 | 25 | 26 | 33 | 34 | 36 | ||

- *1:

- Values under constant ambient temperature

- *2:

- When reciprocating 300mm horizontally and 25mm vertically while conveying 2kg with rough positioning in an arch motion

- *3:

- It is necessary to limit parameters such as acceleration rate to suit allowable inertia

- *4:

- Connected to the main unit rear surface and Y arm upper surface plate

- *5:

- Connected to the main unit rear surface and Y arm inner stay

- *6:

- Does not include the weight of the robot connection cable

Downloads

Zum Download anklicken: