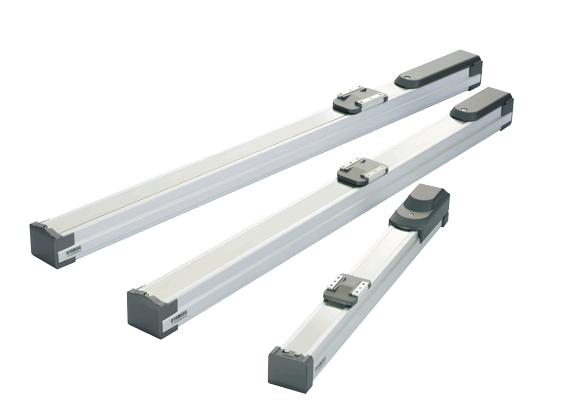

YAMAHA Einachsroboter GX Serie

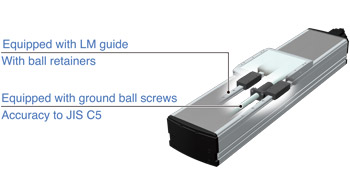

Hocheffiziente, hochpräzise geschliffene Kugelumlaufspindeln gehören bei allen Typen und Modellen zur Standardausstattung. Die hochpräzisen Modelle glänzen mit hoher Zuverlässigkeit und Langlebigkeit.

Vertriebsingenieur Manfred Göschl berät Sie gerne!

Beschreibung

Geschliffene Kugelumlaufspindeln als Standardmerkmal.

Alle Modelle entsprechen der JIS-Norm der Genauigkeitsklasse C5.

- Wiederholbarkeit der Positioniergenauigkeit: ±5µm

- Hubbereich: 50 mm bis 1.450 mm

- Maximale Tragfähigkeit: 160 kg

- Alle Modelle sind mit geschliffenen Kugelumlaufspindeln ausgestattet

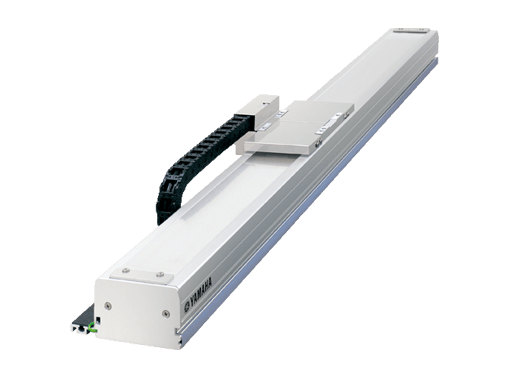

Alle Produktmodelle sind standardmäßig mit hocheffizienten, hochgenauen, geschliffenen Kugelgewindetrieben ausgestattet.

Die Steigungsgenauigkeit entspricht der JIS-Genauigkeitsklasse C5, was eine Wiederholbarkeit der Positioniergenauigkeit von ±5 µm ermöglicht. Die Genauigkeit ist etwa zweimal besser als bei den Vorgängermodellen.

Diese hochgenaue Wiederholbarkeit der Positioniergenauigkeit verbessert auch den Ertrag.

Darüber hinaus ist das Gerät leiser und hat eine längere Lebensdauer.

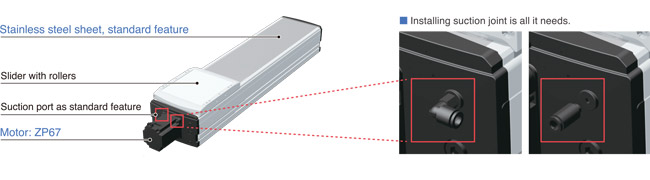

Die Oberseite des Hauptgehäuses ist bei allen Modellen mit staubdichtem, äußerst haltbarem Edelstahlblech ausgekleidet. Diese Anordnung unterdrückt die Verunreinigung durch Fremdkörper von außen. Ein weiteres Standardmerkmal ist der Ansaughahn, der nur eine Rohrverbindung für die Ansaugluft benötigt, um in einer sauberen Umgebung eingesetzt werden zu können.

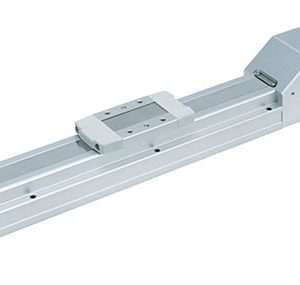

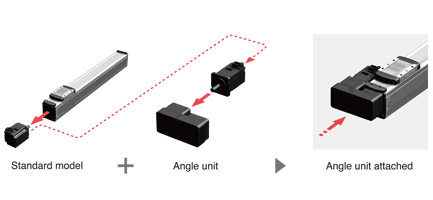

Befestigen Sie eine entwickelte Winkeleinheit an einem Standardmotor. Dadurch können der linke und der rechte Motor die Richtung wechseln, während das Layout der Einheiten eine hohe Dichte aufweist.

Ändern der Position des Roboterkabelauszugs

Die Richtung des Kabelauszugs kann nach Kundenwunsch geändert werden.

Technische Daten

Specification

| AC servo motor output (W) | Repeatability (mm) | Deceleration mechanism (Ground ball screw) | Stroke (mm) | Maximum speed (mm/sec) | Ball screw lead (mm) | Maximum payload (kg) | Rated thrust (N) | Max. external size of body cross-section (mm) | Overall length (Horizontal) mm | Overall length (Vertical) mm | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Horizontal | Vertical | |||||||||||

| GX05 | 50 | ±0.005 | Ф12(Class C5) | 50~800(50mm pitch) | 1333 | 20 | 5 | 2 | 41 | W48xH65 | ST+188 | ST+228.5 |

| 665 | 10 | 8 | 4 | 69 | ||||||||

| 330 | 5 | 13 | 8 | 138 | ||||||||

| GX05L | 100 | ±0.005 | Ф12(Class C5) | 50~800(50mm pitch) | 1333 | 20 | 12 | 3 | 84 | W48xH65 | ST+230 | ST+270.5 |

| 665 | 10 | 24 | 6 | 169 | ||||||||

| 330 | 5 | 32 | 12 | 339 | ||||||||

| GX07 | 100 | ±0.005 | Ф15(Class C5) | 50~1100(50mm pitch) | 1800 | 30 | 10 | 2 | 56 | W70x76.5 | ST+270.5 | ST+311 |

| 1200 | 20 | 25 | 4 | 84 | ||||||||

| 600 | 10 | 45 | 8 | 169 | ||||||||

| 300 | 5 | 85 | 16 | 339 | ||||||||

| GX10 | 200 | ±0.005 | Ф15(Class C5) | 100~1250(50mm pitch) | 1800 | 30 | 25 | 4 | 113 | W100x99.5 | ST+245 | ST+285.5 |

| 1200 | 20 | 40 | 8 | 170 | ||||||||

| 600 | 10 | 80 | 20 | 341 | ||||||||

| 300 | 5 | 100 | 30 | 683 | ||||||||

| GX12 | 400 | ±0.005 | Ф15(Class C5) | 100~1250(50mm pitch) | 1800 | 30 | 35 | 8 | 225 | W125xH101 | ST+297 | ST+337.5 |

| 1200 | 20 | 50 | 15 | 339 | ||||||||

| 600 | 10 | 95 | 25 | 678 | ||||||||

| 300 | 5 | 115 | 45 | 1360 | ||||||||

| GX16 | 750 | ±0.005 | Ф20(Class C5) | 100~1450(50mm pitch) | 2400 | 40 | 45 | 12 | 320 | W160xH130 | ST+339.5 | ST+386.5 |

| 1200 | 20 | 95 | 28 | 640 | ||||||||

| 600 | 10 | 130 | 55 | 1280 | ||||||||

| GX20 | 750 | ±0.005 | Ф20(Class C5) | 100~1450(50mm pitch) | 2400 | 40 | 65 | 15 | 415 | W200xH140 | ST+385.5 | ST+432.5 |

| 1200 | 20 | 130 | 35 | 640 | ||||||||

| 600 | 10 | 160 | 65 | 1280 | ||||||||

Downloads

Zum Download anklicken: